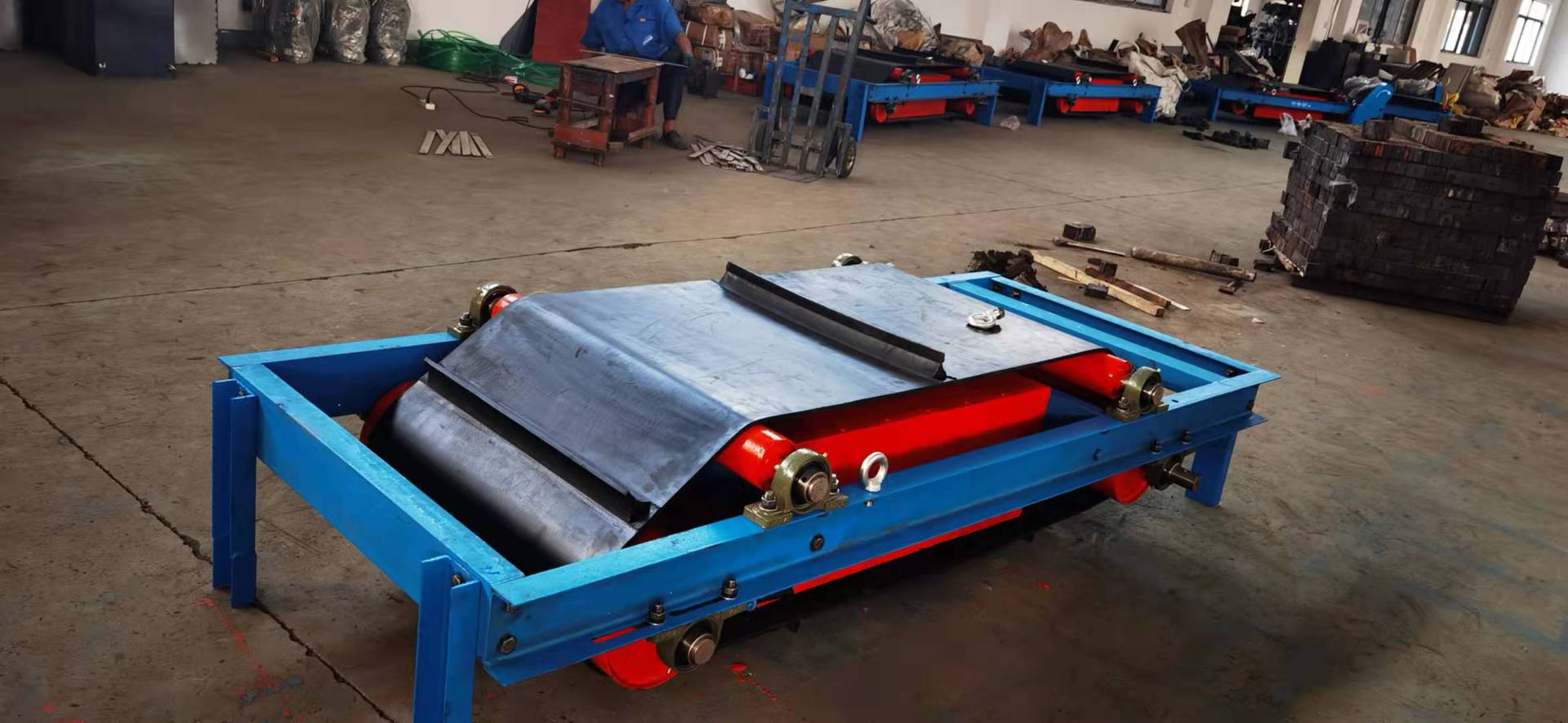

Magnetic separator is a kind of equipment that utilizes the effect of magnetic field to separate the materials containing magnetic substances, which is widely used in many industries. The following is a detailed introduction of the working principle, characteristics and application areas of the magnetic separator:

Working PrincipleThe core working principle of magnetic separator is based on the attraction of magnetic field to magnetic material. The specific process is as follows:

The material enters the separator: the material to be separated enters the separation area of the magnetic separator through the bin.

Material contact with magnetic field: When the material enters the magnetic field area, the magnetic substance will be attracted by the magnetic force and adhere to the surface of the magnetic source.

Separation of magnetic and non-magnetic substances: Magnetic substances are adsorbed to the magnetic source, and with the rotation or movement of the separation device, the magnetic substances will be taken away from the original material flow and finally discharged. The non-magnetic substances, on the other hand, as they are not attracted by the magnetic field, will flow with the material and be discharged from the separator.

Collection and Discharge of Magnetic Substances: The magnetic substances will be collected and discharged along the discharge chute or recycler of the device after passing through the magnetic source.

Features

The magnetic separator has the following characteristics:

High efficiency: It can separate magnetic substances quickly and efficiently to improve production efficiency.

Environmental protection: Through magnetic separation, effective treatment of waste and resource recovery can be realized, which is conducive to environmental protection.

Automation: It can be combined with automated production line to realize automated production and reduce manual intervention.

Adjustability: adjusted according to the magnetic properties of different materials, suitable for different application scenarios.

Application fields and specific applications

Magnetic separators play an important role in many industries, the following are some of the main application areas and their specific applications:

Mining & Metallurgy

Ore purification: used to extract minerals containing iron from ores, such as iron ore, iron sand, etc., to improve the grade of ores.

Metal Recovery: To separate reusable metals from scrap or mixtures, e.g. to recover metals from municipal and industrial waste.

Manufacturing

Raw material purification: Removal of micro-iron impurities from raw materials to ensure product quality.

Product purification: Removal of microfine particles in the production of metals, glass and ceramics to improve product purity.

Environmental and Waste Treatment

Wastewater Treatment: Reduce environmental pollution by removing metals from sewage and landfill leachate.

Waste treatment: Treatment of waste containing metal fragments or other magnetic impurities for resource recovery and environmental protection.

Biomedical Industry

Cell Sorting: Separate healthy cells and cancer cells for biomedical research.

Molecular separation: separating drug molecules, RNA, DNA and proteins attached to magnetic beads, etc.

Food and Chemical Industry

Food processing: removing iron impurities from grains, cereals and other raw materials to ensure food safety.

Chemical production: separating iron and steel chips from raw materials or products to ensure the smooth running of the production process.

Magnetic separator plays an important role in many industries due to its high efficiency, environmental protection and automation, and is one of the key equipments for material separation and purification

Magnetic Separator-product-MingXin

Magnetic Separator-product-MingXin